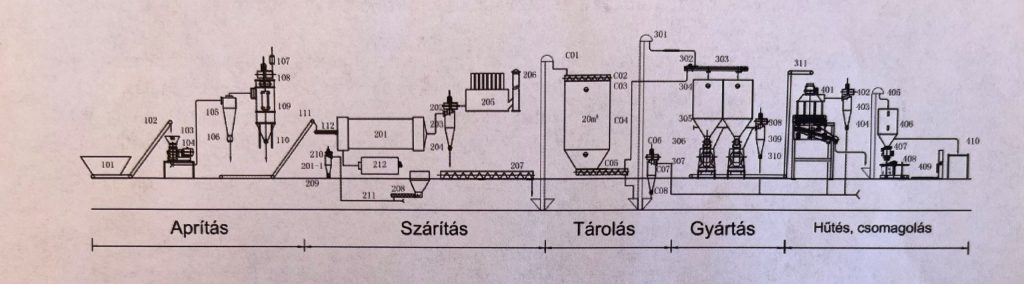

HARD BIO-WASTE PROCESSING LINE

Main equipment and facilities of the plant

- Shredder

- Dryer

- Silo

- Cyclone

- Conditioner

- Press

- Refrigerator

- Rosta

- Packer

(100) Hard bio-waste shredding system

101, Garat (3x2m), approx. 3m3, ldb

With steel frame, grids and outlet flange Steel plate structure with 3mm plate

102, Feeder conveyor ldb

Power: 380 V, 1,5 kW, length: 8m, width: 600mm With one inlet and one outlet

103, Magnetic selector ldb

104, Hammer mill ldb Power: 380 V, 110 kW Grinding chamber width: 800 mm Rotor diameter: 680 mm Rotational speed: 110m/s Rotor speed: 2982 rpm

Number of hammers: 88 hammers, hardened hammers easy to replace Hammer width: 10 mm

Hammer length: 175 mm

105, Cyclone ldb Dimensions: 01000×3300 mm Capacity: 30-40m3

106, Cell feeder 2pcs Power: 380V, 2,2 kW/db Capacity: 21.0001/hour/db

107, Noise absorber ldb Diameter: 450 mm

108, Fan ldb Power: 380V, 30kW Capacity: 7766-9500m3/hr Air pressure: 6527-7218 Pa

109, Filter ldb

Filter surface: 58,7 m2

Filtered air volume: 7766-9500 m3/hr Working pressure of dust collector :::;1200Pa Diameter: 1,9 m

Dust collector resistance: 6000-8000 Pa

110, Cellular feeder ldb Power: 380V, 1,5 kW Capacity: 13440 1/h

111, Conveyor belt ldb Power: 380V, 1,5 kWWidth 600 mm

112, Pulley feeder ldb Power: 380V, 3 kW Capacity: 3t/hr

Pulley diameter: 320 mm Chamber diameter: 330 mm Carbon steel structure

(200) Drying system

201, Drying drum ldb

Power: 380V, 7,5 kW Size: D2650xH9100 mm Weight: 24500 kg

Capacity 3000 kg/h

Speed: 10 rpm/min

Insulation material aluminium silicate, thickness 50 mm Structure material 8 mm thick carbon steel

3-passenger structure

201-1, Cyclone ldb

Size: D600xl730 mm Capacity: 2198-3215 m3/h

202, Fan ldb Power: 380V, SS kW

Capacity: 25663-48410 m3/h

Air pressure: 2216-3050 Pa Silencer 800 mm diameter

203, Cyclone ldb

Dimensions: D1200x3410 mm Capacity: 60-80 m3

204, Cellular feeder ldb Power: 380V, 3 kW Capacity: 75600 1/hour

205, Dust collector ldb

Dimensions: 5520 mm x 1500 mm x 3800 mm

Capacity: 25663-48410 m3 /h

Volume of air passing through: 25663-48410 m3/h Number and size of filters: 6pcs, D300 x 1500 mm

206, Chimney ldb

Diameter: 600 mm

207, Pulley feeder ldb Power: 380V, 3 kW

Capacity: 2:: 3 t/h Auger diameter: 320 mm

Chamber diameter: 330 mm with carbon steel structure

208, Screw feeder ldb Power: 380V, 1,1 kW Capacity: 1,5 t/h

Auger diameter: 200 mm Chamber diameter: 220 mm

Variable speed drive version with carbon steel structure

209, Cellular feeder ldb Power: 380V, 1,1 kW Capacity: 75601/h

210, Fan ldb Power: 380V, 5,5 kW Capacity:2198-3215 m3/h Air pressure: 3407-3825 Pa

211, Pipe system (for fuel storage)

212, Boiler and fuel storage ldb Power: 8,15 kW

( COO) Dry fuel storage

C01, Serial lift ldb Power: 380V, 2,2 kW Capacity: 3 t/h

C02, Screw feeder ldb Power: 380V, 3 kW Capacity: 2:: 3 t/h

Auger diameter: 320 mm Chamber diameter: 330 mm Carbon steel structure

C03, Level indicator 2pcs

C04, Storage ldb

Capacity: 20m3

COS, Twin screw feeder ldb Power: 380V, 4 kW Capacity: 2:: 3 t/h

Auger diameter: 250 mm Chamber diameter: 270 mm

Variable speed drive version with carbon steel structure

C06, Fan ldb Power: 380V, 5,5 kW Capacity: 2198-3215 m3/h

Air pressure: 3407-3825 Pa

C07, Cyclone ldb

Size: D600 x 1730 mm Capacity: 2198-3215 m3/h

C08, Cellular feeder ldb Power: 380V, 1,1 kW Capacity: 75601/hour

(300), hard biowaste BTT production

301, Serial elevator ldb Power: 380V, 2,2 kW Capacity: 3t/h

302, Magnetic selector ldb

303, Chain conveyor ldb Power: 380V, 2,2 kW Capacity: 3 t/h

Size: 300 mm wide carbon steel structure

304, Level indicator 2pcs

305, Dry material hopper 2pcs Power: 380V, 2 kW Capacity: 2,5 m3 Carbon steel structure

306, Conditioner 2pcs

Size: 2741x955x600 mm Inlet opening: 244×244 mm Outlet opening: 249×192 mm

307, BTT mill 2pcs Power: 380V, 271,4 kW Number of rollers: 2pcs

Internal diameter of matrix: 508 mm

Die material alloy steel, oil cooled

308, Fan ldb Power: 380V, 3 kW Capacity:2664-5768 m3/h Air pressure:989-1578 Pa

309, Cyclone ldb Capacity: 2664-5768 m3/h Size: D800x2100 mm

310, Cell feeder ldb Power: 380V, 1,1 kW Capacity: 75601/hour

311, Conveyor belt ldb Power: 380V, 3 kW Size: 600 mm wide

(400) BTT cooling and packaging system

401, Refrigerator and vibrating feeder ldb Power: 380V, 1,47 kW Capacity: 3 t/h

Size: 1,25 m2

ldb grate with 19° tilt angle Vibration motor speed: 1000 rpm

402, Fan ldb Power: 380V, 11 kW

Capacity:7728-15455 m3/h Air pressure: 2019-3187 Pa

403, Cyclone ldb

Capacity:7728-15455 m3/hr Size: D1000x2800 mm

404, Cell feeder ldb Power: 380V, 1,1 kW Capacity: 7560 1/hour

405, Serial elevator ldb Power: 380V, 2,2 kW Capacity: 3 t/hr

406, Pre-packing BTT storage ldb Size: 1300x1300x2000 mm, approx. 6,5m3

Fitted with distribution valve to bagging and big-bag filling packing units

407, Packaging machine ldb Power: 380V, 1,5 kW

Packing speed: 4-5 bags/min Weight distribution: 15-50 kg/bag

The packing unit automatically fills and weighs the bags and transports them to the palletiser on a conveyor belt.

408, Foil sealer ldb Power: 380V, 0,75 kW

Wall thickness of the bag: :5 0,2 mm

Bag height: 450-750 mm Soldering length: 700 mm

409, Pallet wrapper ldb Power: 380V, 1,5 kW

Max. load capacity: 2000 kg Diameter of forming ramp: 1500 mm Max. height of foil: 2100 mm Weight of technology: 550 kg

410, Big-bag bag loader ldb Fitted with bag holder unit